Hydraulic Fluid Contamination: Prevention & Resolution

Approximately 70 to 80% of all hydraulic system failures are directly related to hydraulic fluid contamination. Caused by debris, particles, or substances polluting your system, contamination can bring your work to a standstill. By recognizing the signs that hydraulic fluid contamination has occurred, determining the contamination source, and taking steps to address or prevent contamination from happening, you can extend the lifespan of your cylinders and improve the operational capacities of your equipment.

Signs of Hydraulic Fluid Contamination

Hydraulic fluid contamination can seriously impact the operations of your hydraulic cylinders and equipment. Signs that contamination has occurred include:

- Reduced efficiency and performance

- Internal leaking

- Sludge in hydraulic oil

- Complete system failure or cylinder shutdown.

How Hydraulic System Contamination Occurs

Hydraulic fluid contamination is caused by a variety of issues that can contribute to poor performance and unnecessary wear, leading to expensive downtime and lost revenue. The best solution for hydraulic system contamination will depend on the source of the contamination.

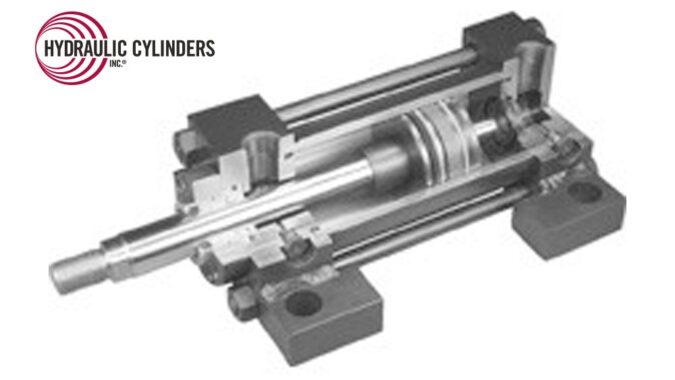

Water in the Hydraulic Fluid

Water in hydraulic fluid is the most common type of contamination. When moisture is introduced, problematic chemical reactions can occur, resulting in liquid settling on the bottom or floating to the surface of the reservoir. The water in your system can lead to corrosion, causing breakdown over time and introducing contaminants that are suspended within the hydraulic fluid.

To avoid water in your hydraulic fluid, always check your system’s reservoir for water, then bleed as necessary.

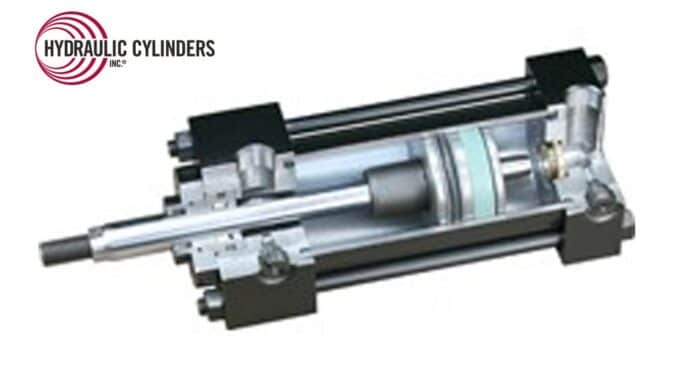

Hydraulic Cylinder Wear

Wear can lead to contamination. An improper seal, worn piston, and other damaged or worn components can introduce particles as small as 2 microns, adversely affecting pump life, causing leaks, and impacting overall system performance. By identifying, replacing, or repairing worn components, you can address the issue before expensive or catastrophic consequences occur.

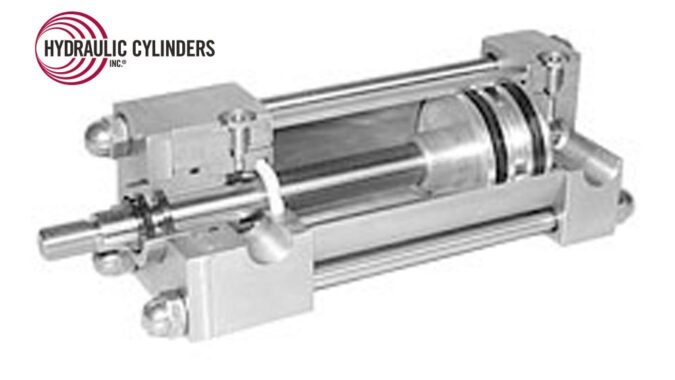

Mistakes During Assembly or Reassembly

Contamination can occur during the initial assembly, maintenance, or repair of a hydraulic system. Debris and contaminants can enter when the cylinder is disassembled and then become trapped. To avoid this outcome, always carry out all maintenance and repair in a clean and controlled space. If you believe that hydraulic cylinder contamination occurred during manufacturing, reach out to your supplier immediately to arrange a solution.

How to Avoid Hydraulic Fluid Contamination

No matter the contamination source, regular system maintenance and upkeep is the number one way to ensure contamination does not occur. During your scheduled maintenance, be sure to:

- Complete all processes in a clean, clear area

- Examine all component parts for wear or signs of hydraulic system contamination

- Flush fluid on a regular basis

- And other solutions specific to your equipment parameters.

Proper maintenance and repair measures will not only extend the life of your hydraulic cylinder, but they will reduce contaminants in your system, allow you to identify issues as early as possible, and demolish downtime for your job site.

Get Back to Work as Soon as Possible with Hydraulic Cylinders, Inc.

Whether you’re looking to replace worn cylinder component parts or are ready to purchase a new replacement cylinder, HCI has you covered. We offer same-day shipping on all in-stock orders to get your equipment up and running with minimal delays. Custom-manufacturing services are also available to match the needs of specialty or discontinued equipment.

Ready to get started? Contact us or request a quote today!