Bobcat Hydraulic Cylinder Replacement Cylinder Advantages

Which is better, aftermarket hydraulic cylinders or Bobcat OEM cylinders? It is an age-old question for which there is not a clear cut answer. Preferences often dictate subjective responses. It is easy to find OEM enthusiasts as well as aftermarket enthusiasts. Regardless of enthusiasm or preferences, there are factors to consider when choosing an aftermarket custom hydraulic cylinders.

Which is better, aftermarket hydraulic cylinders or Bobcat OEM cylinders? It is an age-old question for which there is not a clear cut answer. Preferences often dictate subjective responses. It is easy to find OEM enthusiasts as well as aftermarket enthusiasts. Regardless of enthusiasm or preferences, there are factors to consider when choosing an aftermarket custom hydraulic cylinders.

Factors to Consider for Aftermarket Hydraulic Cylinders

Some important factors to consider when choosing between aftermarket hydraulic cylinders and OEM cylinders include:

- Technical Support. Hydraulic cylinder wear and tear is unfortunately unavoidable. Hydraulic cylinder seals are susceptible to rapid wear when exposed to extreme temperatures or fluid contamination. Knowing whether to use replacement parts for wear and tear requires expert hydraulic cylinder knowledge. Working with a reputable aftermarket manufacturer can save you time and money by being able to address your hydraulic cylinder issues quickly, with the best solution for your needs.

- Supplier Network. With supply chain issues becoming increasingly volatile, it is important to work with a manufacturer that has a trusted network of suppliers. In addition to having technical expertise, supplier networks that have been vetted and approved by reputable manufacturers mean you no longer have to worry about supply chain issues or turnaround times for custom hydraulic cylinders and parts.

- Like many things, quality is often subjective. What is not subjective is performance standards and engineering. Tight tolerances or custom specs with aftermarket hydraulic cylinders means higher performance than OEMs, often at a better price.

- Inventory Availability. It might be a tired cliché, but time is money. Working with an aftermarket manufacturer that carries performance-built hydraulic cylinders that are in-stock with multiple warehouse locations is essential for most businesses. Less downtime for you benefits you and your clients, regardless of the cylinder issue you need to resolve.

Learn more about HCI’s aftermarket hydraulic cylinder advantages

Bobcat Hydraulic Cylinder Repair Issues

As a major hydraulic cylinder manufacturer, Bobcat cylinders are known for their performance advantages over other hydraulic cylinder brands. But what happens if your Bobcat cylinder leaks and your cylinder seal needs replacing? When Bobcat cylinders falter, many owners will attempt to take the cylinder apart in an attempt to service the cylinder. This can include attempting to unscrew the aluminum heads from the iron barrel, but they cannot unscrew from the barrel. There is a chemical reaction between the aluminum and the iron that makes this endeavor virtually impossible.

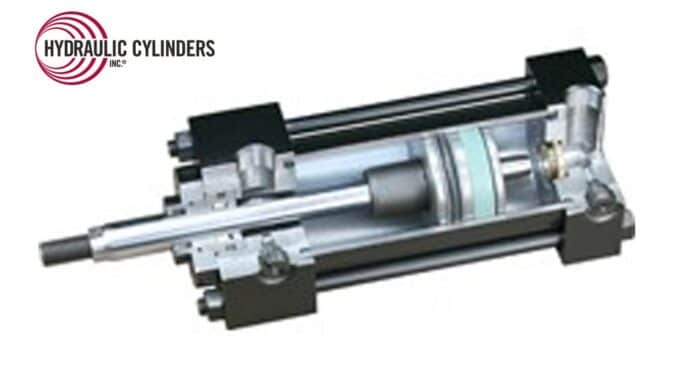

By attempting the difficult feat of unscrewing the heads from the barrel, it is easy to destroy your hydraulic cylinder. When this occurs, a total hydraulic cylinder replacement is the next viable option. Servicing the hydraulic cylinder would be the easiest and least expensive option, preferable to a complete replacement. That is where aftermarket Bobcat cylinders come into play. HCI manufactures aftermarket Bobcat cylinders with ductile iron heads, allowing you to take your cylinder apart with ease.

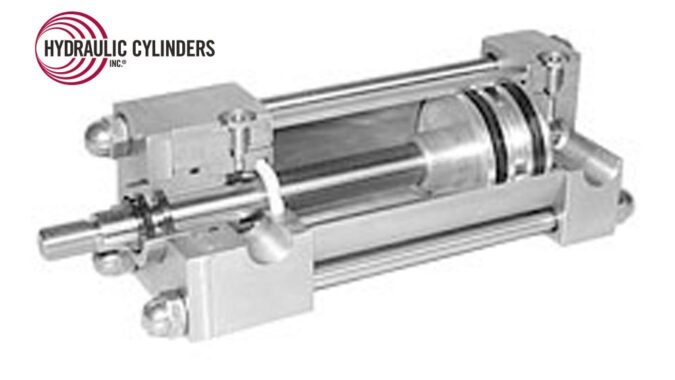

Superior Engineering and Design that Exceeds OEM Specifications

HCI’s engineers have utilized their experience to design a hydraulic cylinder that meets or exceeds OEM specifications when compared to OEM Bobcat cylinders.

HCI Hydraulic Cylinder Design Advantages

- Ductile Iron Head Gland with Buttress Threads versus the aluminum OEM gland

- means less galled or damaged threads

- Ductile Iron Piston with Replaceable Bearing versus the aluminum OEM piston

- results in less wear and longer cylinder life.

- Highest quality seals used

- results in extended seal life.

- SAE or JIC Flared Ports

- Results in less leak

- Proudly manufactured in the USA

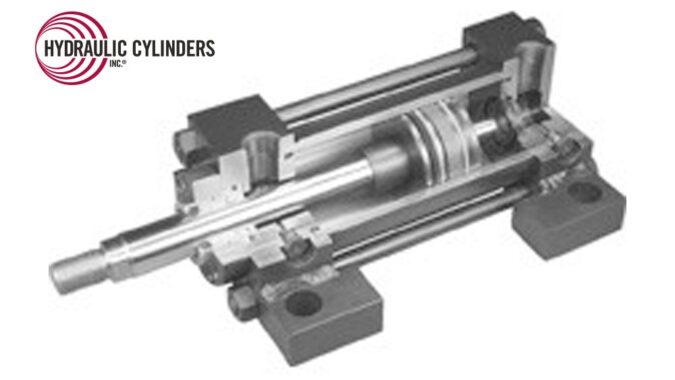

Replacement Bobcat Hydraulic Cylinder Specification Information

- Piston Rod: 1045/1050 Cold Drawn (75 KSI Min. Yield

- Induction Hardened To .050 Deep Min. @ Rc Min.

- Chrome Plated Thickness .0005 Min, Hardness of Chrome 69-71 Rc

- Surface Finish 16 Rms MAX, which is less susceptible to bending

Explore our aftermarket Bobcat hydraulic cylinders and parts.

Order a High-Performance Aftermarket Bobcat Hydraulic Cylinder

With a trusted supplier network, in-stock inventory that is ready to ship, and technical support online or by phone, HCI has the high-performance Bobcat hydraulic cylinders that are ready to work for you. With specifications that outperform OEM Bobcat cylinders and parts. Get started today and order an aftermarket Bobcat hydraulic cylinder. For technical assistance or more information, please contact us or call us at 1-866-817-9043.