- Stroke – The travel of the cylinder; extended length (pin to pin center) minus the retracted length (pin to pin center).

- Retract – The length pin to pin center when a cylinder is fully closed.

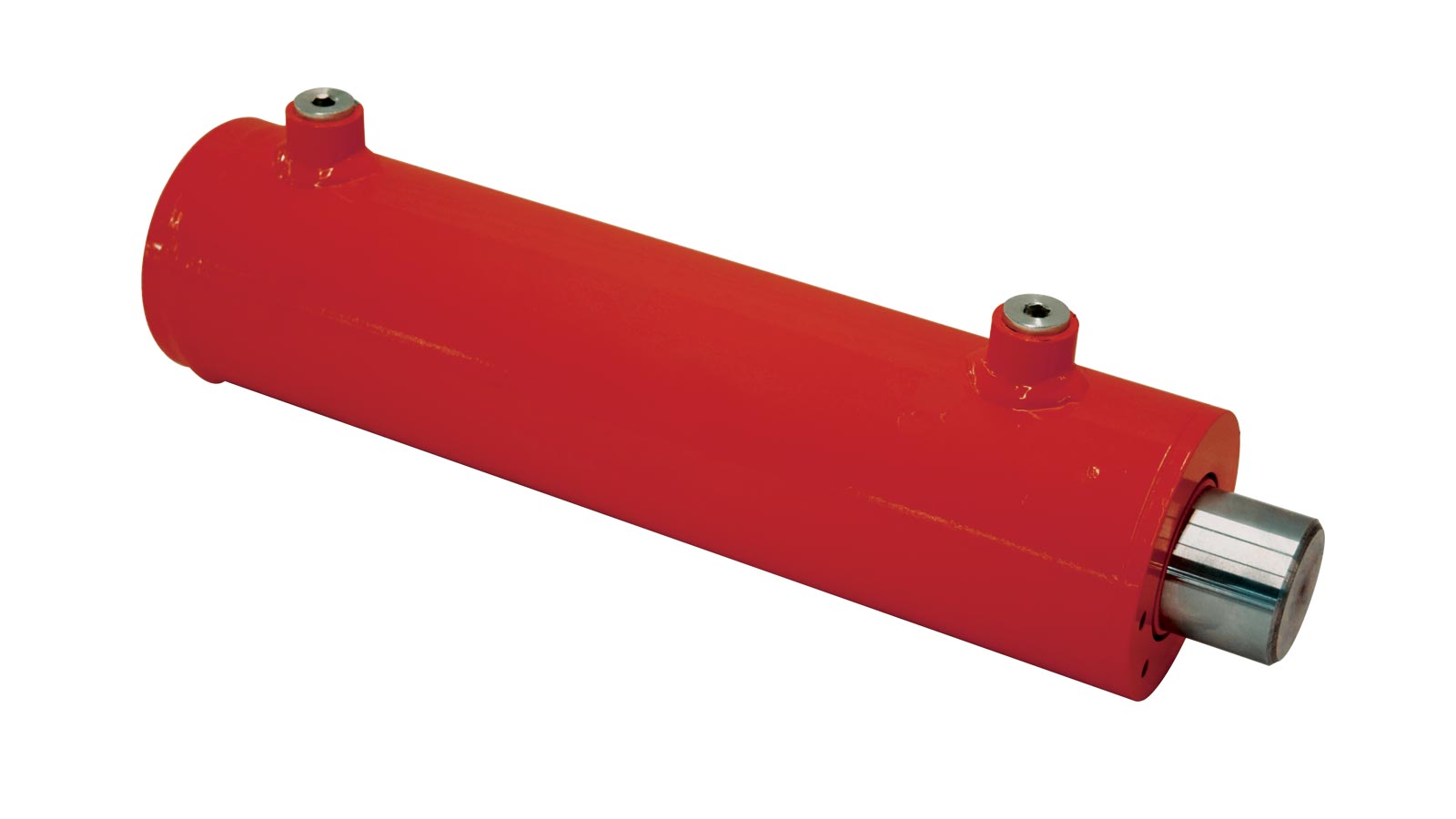

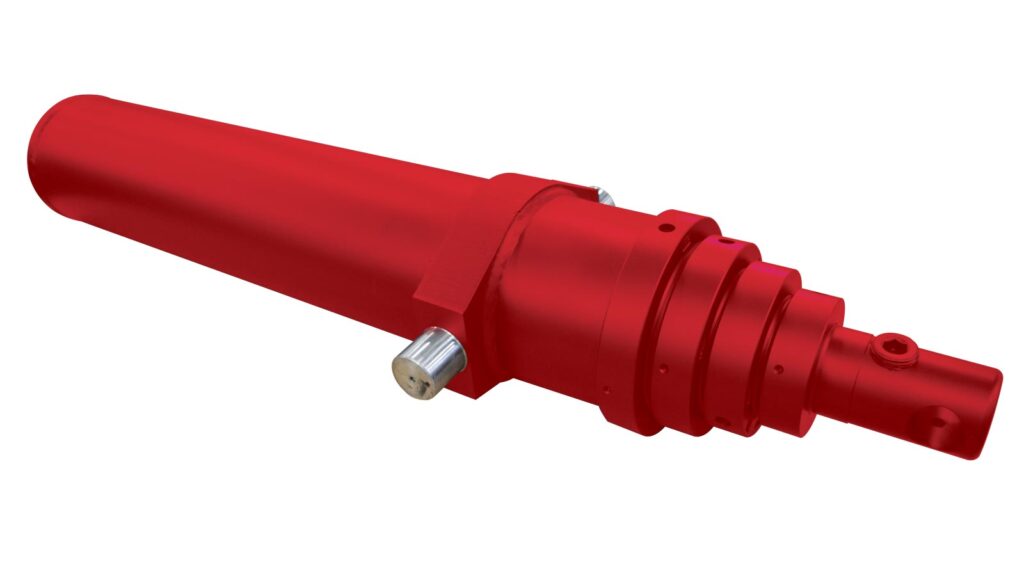

- Rod/Ram/Cylinder Shaft – The round device that moves in and out of the cylinder. Cylinder rods can be solid or hollow and are usually plated or heat-treated to improve wear and corrosion resistance.

- Bore – The inner diameter of the cylinder barrel.

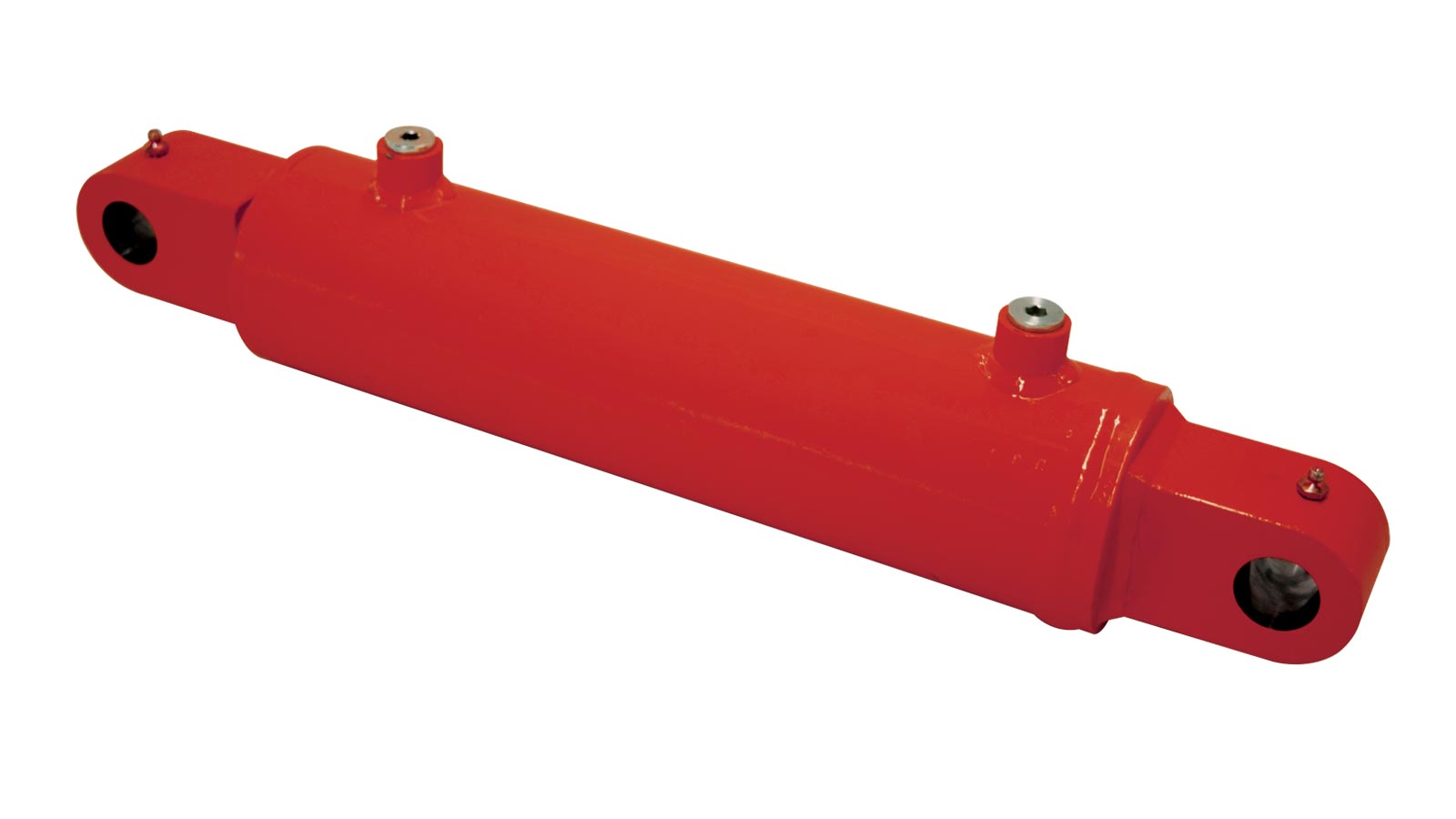

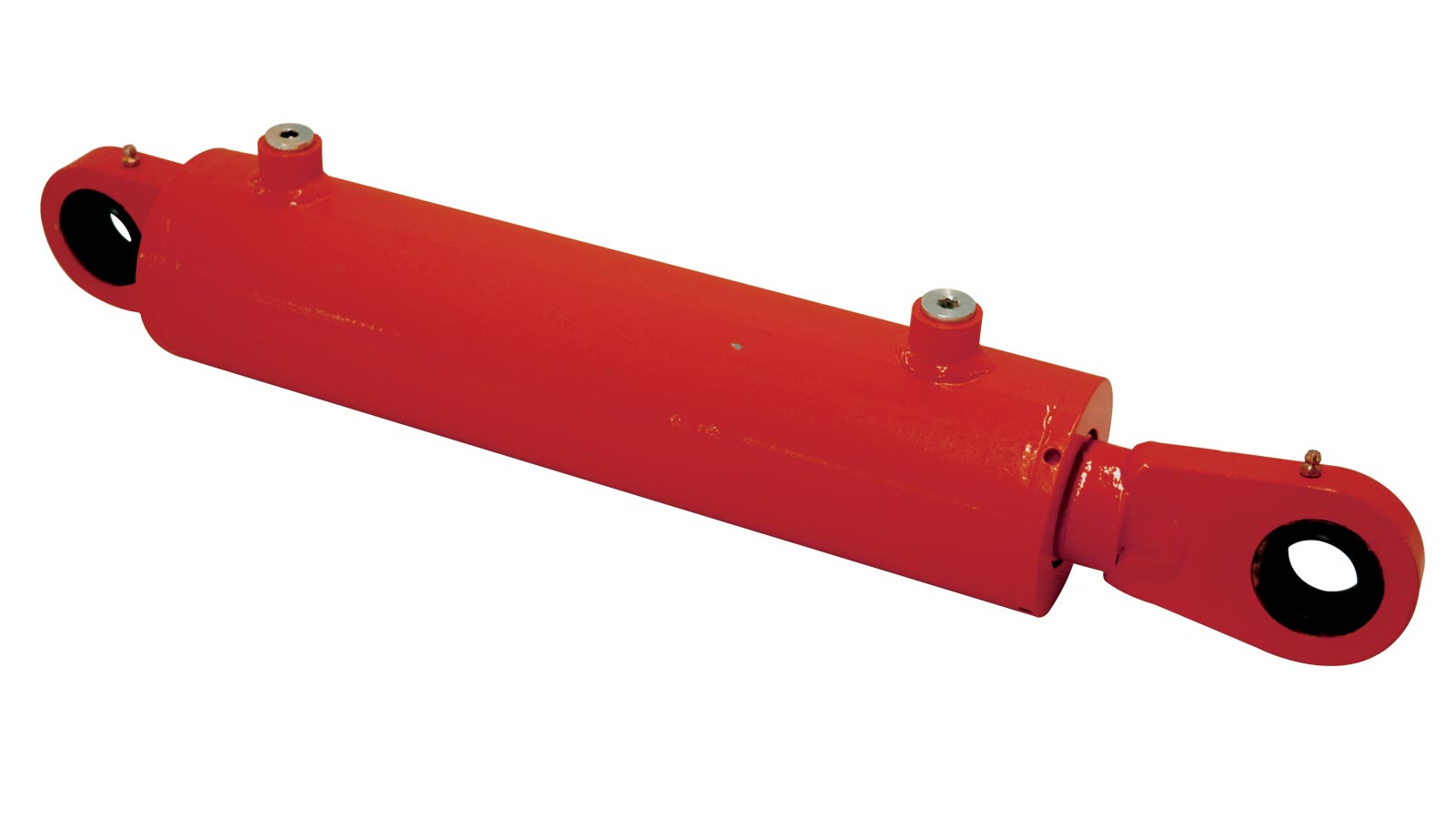

- Cylinder Barrel – The barrel is the cylindrical body of the cylinder. The barrel guides the piston and provides a sealing surface for the piston seal. The barrel is also the structural part of the cylinder that holds the ends in place.

- Cylinder head gland (Stuffing Box) – The head gland or stuffing box is a cylinder component that serves more than one purpose. It retains the static and dynamic seals at the head end of the cylinder, it seals off at the end of the cylinders, it is the support or guide for the rod and is the mechanical stop to keep the piston from falling out of the cylinder barrel.

- Piston – These cylinder components have multiple purposes: The piston moves back and forth from the hydraulic oil and retains the primary seal from the extend and retract sides of the cylinder. Pistons are the mechanical means of connecting and moving cylinder rods in and out and serves as a guide for one end of the piston rod.

- Piston rod – The rod is also known as the cylinder shaft or ram. It is the round device that moves in and out of the cylinder. The piston rod can be solid or hollow. The rod is usually plated or heat-treated to provide better wear and corrosion resistance.

- Seals – Positive seals create a seal with non-leakage. A static seal is a seal that does not move. Dynamic seals seal a moving surface like a rod or a barrel.

- Cushion – A cushion is an option on a cylinder that slows it down before the travel reaches the end of the stroke. Cylinder cushions can be installed on the extend side of the cylinder, on the retract side, or both. Cushions keep the cylinder and the load from banging, helping to reduce noise and increase the life of the apparatus it is moving.

- Port – Cylinder ports are used to connect fluid lines or conduits to the cylinder. An O-ring Boss (SAE) Port has straight or parallel threads and an O-ring to seal the threads. Pipe Ports have tapered pipe threads that use interference between the male and female threads to create a seal. 4-Bolt Flange Ports feature four bolts that hold the two halves together and an O-ring seal. BSP is a British Standard Pipe Thread.

General Hydraulic Cylinder Questions

The part number is stamped onto the barrel of your hydraulic cylinder and is usually 5-10 digits long.

Hydraulic cylinders are categorized by bore, rod, and stroke measurements. You will also need to know the pressure and flow requirements for you application. Our guide and video walk you through the steps of getting accurate measurements.

Most of the hydraulic cylinders and component parts we stock are designed and manufactured in America.

- Double-Acting (DAT) – Have a port at each end, supplied with hydraulic fluid for retraction and extension.

- Single-Acting (SAT) – Hydraulic fluid enters through a port at one end of the cylinder, extending the rod by means of area difference. An external force or gravity returns the piston rod.

Read our blog post to learn more about the differences and advantages of each option.

- Side Loading – Side loading is caused by cylinder misalignment, which creates an unusual force on the piston rod. A side load of enough magnitude can cause tube scoring, piston rod and rod bearing wear, and seal failure.

- Contaminated Fluid – Contaminated fluid can cause premature rod seal failure. Abrasive particles in the fluid can damage the seal and the piston rod surface; airborne contamination can be drawn into a cylinder by a faulty wiper seal. Contamination occurs in numerous ways, but the most common source is contaminants from oil or the pump.

- Rough Or Scored Rod – Rough places on the rod damage the seals and reduce their normal life, resulting in frequent replacement.

Read the full blog post to learn more.

Ordering, Shipping, and Returns Questions

Log in to your account to check your order status 24/7.

Each cylinder is packaged with extreme care and shipped using a custom pallet wrapped in a protective covering to prevent damage. Items less than 150 lbs. ship via small parcel carrier. Anything over 150 lbs. ships via freight. Learn more.

Orders of in-stock items placed before 12:00 PM CST Monday-Friday are processed and shipped the same day (except holidays). Orders placed after the cutoff time will ship the next business day. Learn more.

Shipping costs depend on the package weight, shipping method, and distance. All charges are automatically calculated during check-out for stock items, or before shipping your custom order. Learn more.

No, we are unable to ship to PO boxes. Learn more.

New, unused stock items can be returned within 30 days of purchase. Read our full return policy.

Custom Quote Questions

If you know your exact specifications, you can submit a quote using our Cylinder Calculations App. Anyone requiring non-standard measurements or features or who needs design help should use our quote request form to submit their request.

We turn quotes for standard and in-stock cylinders around within 24 hours. Custom quote turnaround depends on the cylinder type and your design and engineering requirements.

The short answer is, “it varies.” Factors like material availability and delivery schedules dictate how quickly we can get materials from our U.S. suppliers. We must also factor in time for designing and manufacturing your custom cylinders, then shipping them to you. Our team works hard and has a network of suppliers dedicated to helping us get your custom cylinder project turned around as quickly as possible.