Navigating Your Hydraulic Cylinder Components

A Breakdown of Hydraulic Cylinder Components

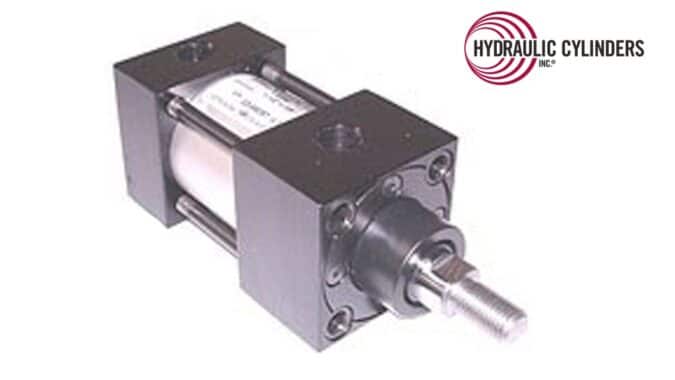

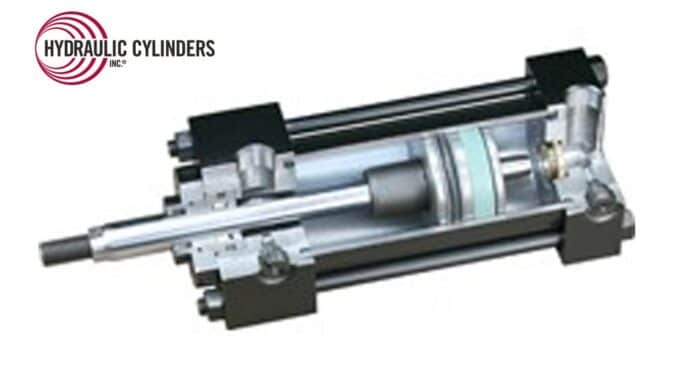

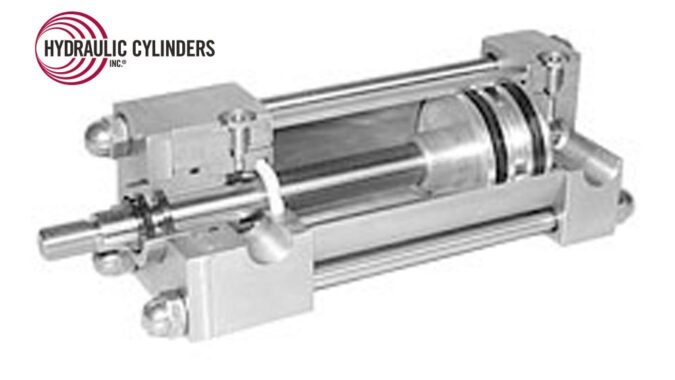

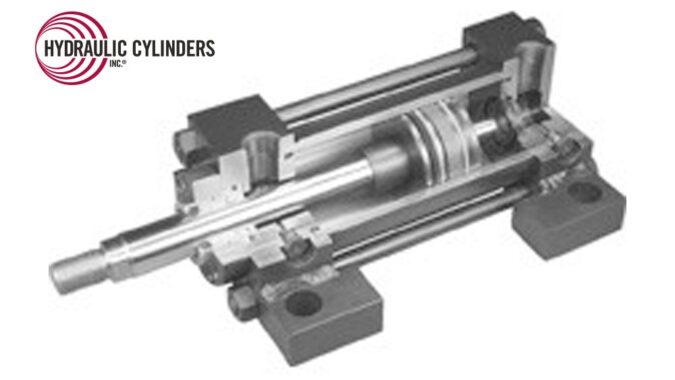

A hydraulic cylinder is primarily built inside a barrel fabricated from a seamless steel tube. The barrel is the main body of the hydraulic cylinder and holds the pressure of the cylinder inside and houses components that make up the hydraulic cylinder.

Cylinder Base

The cylinder base encloses the barrel at one end and can be connected to the barrel with a weld, threading, bolts or tie rods. The base holds the mounting solution at one end of the cylinder and seals it tight to maintain pressure and prevent fluid from escaping. Mounts or welds secure the base and hydraulic cylinder to the body of your mobile equipment.

Cylinder Head

On the other end of the barrel is the cylinder head. The head maintains hydraulic pressure by closing off the other end of the barrel and allowing the piston to extend and retract while under pressure. Cylinder heads contain seals and bearings that seal the barrel, head, and opening and align the piston rod.

Piston

Inside the barrel, the piston is the component attached to the rod that bears the force of the hydraulic fluid, allowing it to extend or retract. A piston is often machined with several grooves to allow seals to fit around it and maintain hydraulic pressure inside the barrel. The piston transfers its power to the piston rod and is attached by threads, bolts, or nuts.

Piston Rod

The piston rod is typically a hard chrome-plated piece of cold-rolled steel attached to the piston and extends from the cylinder through the head. The piston rod connects the hydraulic cylinder to the machine component doing the work, such as a plow or dump body. The mounting attachment attaches directly to the piston rod.

Types of Hydraulic Cylinder Seals

In many build styles, the cylinder head contains a seal gland that houses specific types of hydraulic seals to prevent pressurized oil inside the barrel from leaking past the interface between the rod and the head. The advantage of a seal gland is easy removal for seal replacement.

Seal glands typically contain a primary seal, secondary seal/buffer seal, bearing elements, wiper/scraper, and static seal. In some cases, especially in small hydraulic cylinders, the rod gland and bearing elements are made from a single integral machined part.

Hydraulic seals, like the hydraulic cylinder itself, are specified based on cylinder working pressure, cylinder speed, operating temperature, and application. Seals used on hydraulic cylinders are dynamic and must be able to stand up to the wear of the piston rod extending and retracting.

Seals are generally made from nitrile rubber, Polyurethane or Teflon, and are best in lower temperature environments. higher temperatures, hydraulic seals made of Fluorocarbon are a better option. Metallic seals are also available and commonly use bronze for the seal material. Wipers are often made from polyurethane and are used to eliminate contaminants such as moisture, dirt, and dust, which can cause extensive damage to cylinder walls, rods, seals, and other internal components.

High-Performance Hydraulic Seals and Component Parts

Hydraulic Cylinders, Inc. offers American-made replacement cylinders, seals, and component parts for mobile equipment. With a rugged, performance-built design, our cylinders deliver precision and performance under extreme work conditions.

If you need replacement components and seals, reach out to one of our hydraulic cylinder experts at 866-817-9958. We’ll help you determine the best route to take to eliminate your downtime.