Choosing a Custom Hydraulic Cylinder Manufacturer

Designing a custom hydraulic cylinder may seem like a daunting task, but with the right engineering team, you can create a hydraulic cylinder that can meet your application’s demands. Standard, general-use hydraulic cylinders are manufactured to be multi-purpose. While they may be constructed with decent materials, they may not be able to withstand the daily demands required for specific application needs.

The Right Cylinder System for Your Application Needs

Versatile and generally easy to maintain, pneumatic cylinders are useful for a wide range of applications. With the ability to move diverse payloads, pneumatic cylinders provide acceptable positional accuracy for applications where high force is needed.

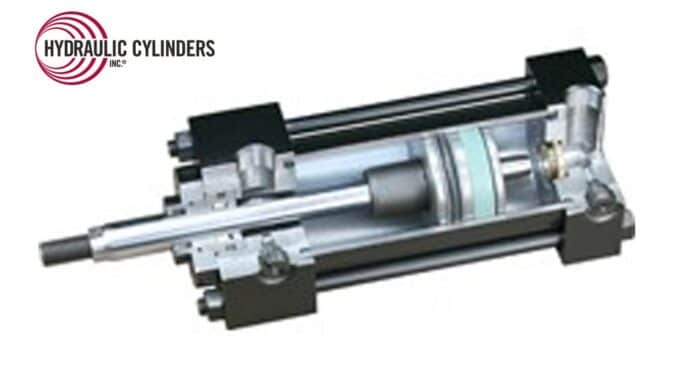

Hydraulic cylinders are ideal for applications that require brute force and moving high loads. Generally, hydraulic cylinders can move 10 to 100 times the force of pneumatic cylinders. Hydraulic cylinders also provide smoother movement, with controllability that cannot be found in pneumatic cylinders. The controllability leveraged by hydraulic cylinders results in more accurate positioning when in use.

Design Considerations for Custom Hydraulic Cylinders

Ultimately, multiple factors will determine what components will need customization and what components are acceptable as standard issue. Industry guidelines and standards can play a role in component customization and hydraulic design. Additional design considerations include:

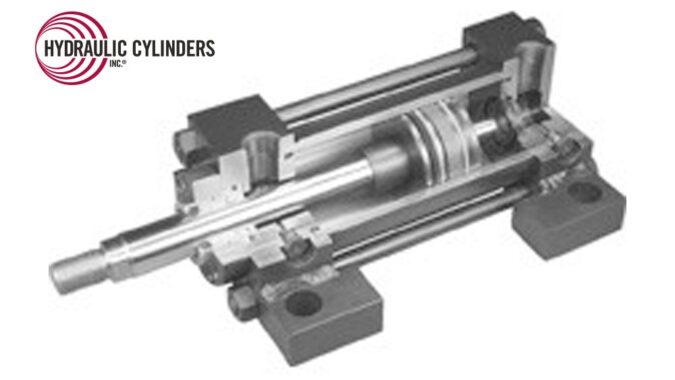

- Most hydraulic cylinders can be categorized into medium-duty and heavy-duty designations. Medium-duty hydraulic cylinders can accommodate most industrial uses and are primarily rates at 1,000 psi. Heavy-duty hydraulic cylinders are ideal for presses and automotive and can accommodate up to 3,000 psi.

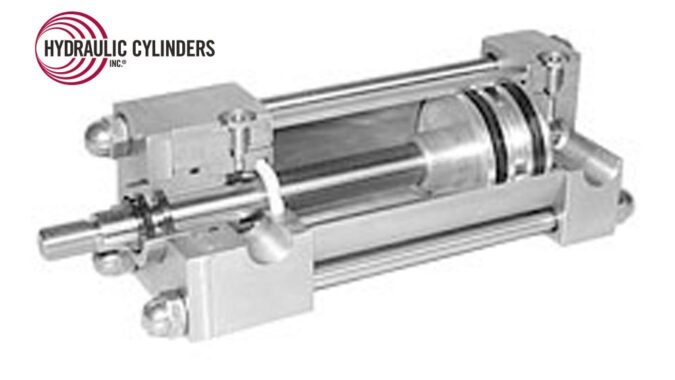

- Cylinder body type material. Hydraulic cylinders can be manufactured with a steel- or chrome-plated body. Depending on your application, custom hydraulic cylinders can be made with alloy steels such as stainless steel or brass.

- Cylinder bore size. The force required determines bore size as it is relative to operating pressure.

- Cylinder configurations. Configurations depend on your application needs. Custom hydraulic engineers should work with you to determine the best configuration to meet your application and performance requirements.

- Mounting styles. The three types of mounting styles for hydraulic cylinders include:

- Fixed mounts. Absorb forces and can include medium-duty and heavy-duty mounts.

- Pivot mounts. Similar to fixed mounts, pivot mounts absorb forces and can include medium-duty and heavy-duty mounts.

- Off-set pivot mounts. Mounts below the centerline and supports the entire cylinder.

- Piston rod size. Custom piston rod sizes can be manufactured in various alloys, depending on the needed column strength.

- Rod ends/threading. Can be made in inch or metric, diameter availability in 4-rod end styles.

- Can be customized based upon application needs and temperature/fluid requirements.

- Average hydraulic cylinders can accommodate speeds up to 3.28 feet per second.

- Stroking distance. Can be customized depending on the application. Pressure rating and rod diameter must be considered when making customizations.

- Stop tubing. Can increase the distance between the rod and piston bearings. Stop tubing can improve stability and enhance piston bearing shelf life.

- Standard hydraulic cylinders can accommodate temperatures ranging from -65° F up to 500° F. Customization should consider environmental factors and weather extremes.

Application-Specific Considerations for Custom Hydraulic Cylinders

When designing your custom hydraulic cylinder, it is important to keep your performance requirements top of mind. One of the major benefits of custom hydraulic design is having the ability to choose materials and configurations that meet your exact application and performance requirements.