The Differences between Standard and Custom-Made Hydraulic Cylinders

The decision to purchase a standard, off-the-shelf hydraulic cylinder or design a custom-made hydraulic cylinder largely depends on your specification requirements and application needs. Off-the-shelf hydraulic cylinders are usually in-stock and ready to ship, making them a quick fix if your hydraulic system has failed to the point of no return. Custom hydraulic cylinders offer you the flexibility to design a hydraulic cylinder to meet exact application requirements.

Both standard and custom hydraulic cylinders have benefits that make each one a decent option. Neither one is necessarily better than the other, however, one can be better suited for your application and thus the better hydraulic cylinder choice for you.

Standard Hydraulic Cylinders

The word standard often implies “simple” or “basic” when, in reality, standard off-the-shelf hydraulic cylinders can be anything but basic. Hydraulic cylinders and components can be ordered off-the-shelf, making them an easy and accessible choice when replacement parts cylinders will meet your hydraulic needs.

Standard hydraulic cylinders can be manufactured with high-quality materials and work great as replacement OEM components and/or as replacement OEM hydraulic cylinders. If you know the manufacturer and product number for cylinder or component, standard options are a hassle-free way to get your mobile equipment up and running again.

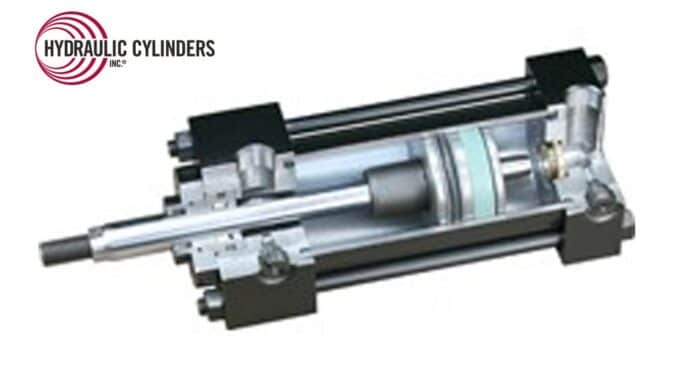

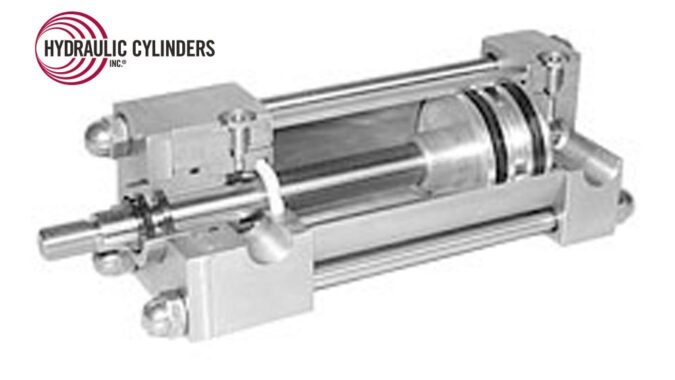

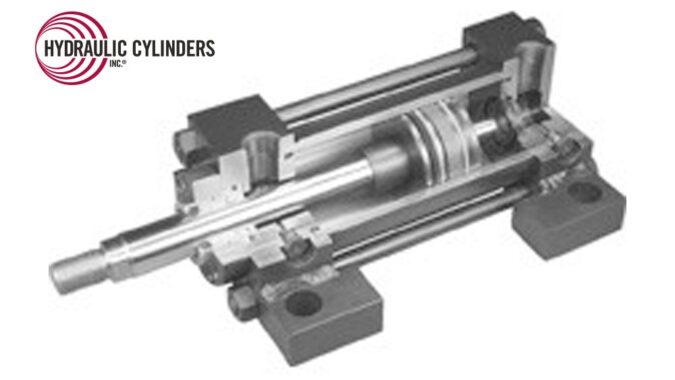

Custom-Made Hydraulic Cylinders

As the name implies, custom-made hydraulic cylinders are customized to fit your equipment/machine needs. One of the major benefits of custom hydraulic cylinder design is that the hydraulic cylinder can be developed with load and lift capacities in mind. Another benefit to custom hydraulic cylinders is the ability to design a high-performance cylinder with specific operating conditions in mind. Operating environments based in tropical climates will have different requirements than environments based in polar climates.

Purpose-built custom hydraulic cylinders can be built with ISO or industry standards in mind. Component materials, compact design, high-efficiency, and mounting options are some ways in which hydraulic designs can be customized. Another important factor with custom-made hydraulic cylinders revolves around the engineering team you work with. Experience is obviously a factor for consideration when designing a custom cylinder, however other factors including workflow process, turnaround times, as well as innovative and industry-specific solutions are all aspects to evaluate before deciding on a custom-built hydraulic cylinder.

Which Hydraulic Cylinder Type is Right for You?

Your application requirements can serve as a foundational guide for your decision on whether a standard built hydraulic cylinder or a custom-made hydraulic cylinder is right for you. If you believe a custom hydraulic cylinder is right for you but don’t know where to begin, discuss your application requirements with HCI. With a vast selection of OEM cylinders and components as well as custom telescopic and welded rod cylinder capabilities, we can help you determine what type of cylinder will work best for you.

Check out HCI’s replacement hydraulic cylinders and hydraulic component parts. If you need more assistance with selecting the best replacement hydraulic cylinder, call us at 1-866-817-9071.