Considerations for Custom Telescopic Cylinder Design

Telescopic cylinders can be customized for a variety of industrial applications, fleets, and machinery. While designing your custom telescoping cylinder, it is essential to address your exact challenges to ensure optimal performance over long operational lifespans. Whether you have unique work requirements, specialized machinery, or simply require a non-standard solution, custom telescopic cylinders are your best choice.

Custom Telescoping Hydraulic Cylinders Designed for Your Needs

Custom telescopic cylinder design has no one-size-fits-all answer. To create the best solution for your hydraulic system, keep these considerations in mind:

- Telescopic cylinder constructions

- Required stages and seals

- Desired load capacity

- Anticipated work conditions

- And other elements specific to your needs!

These factors, along with others, will influence your custom telescoping cylinder design. Always consult your equipment’s manufacturer’s manual for specifications, and call 888-771-1894 to receive assistance from an expert member of the Hydraulic Cylinders, Inc. team.

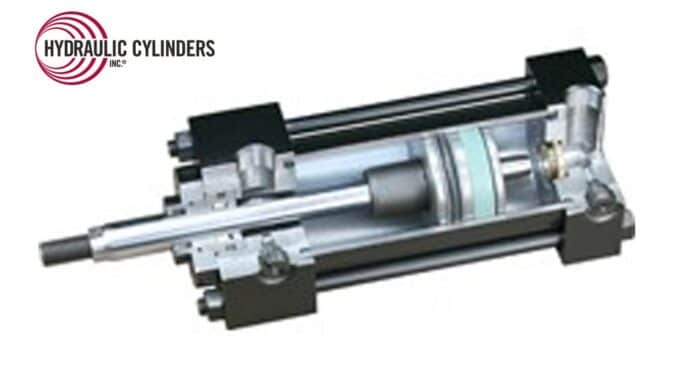

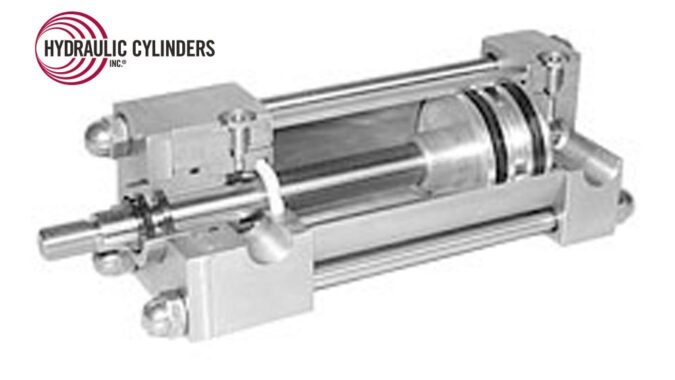

Single-Acting vs. Double-Acting Telescopic Cylinders

Telescopic cylinders are available in two main configurations: single-acting and double-acting. Your best option will depend on the rigors and demands of your job:

- Single-acting telescopic cylinders extend using hydraulic power but need gravity or another external force to retract. They are a low-cost, low-maintenance cylinder used in dump trailers and other mobile equipment.

- Double-acting telescopic cylinders extend and retract using hydraulic power. They deliver increased versatility, precision, and control to mobile and industrial hydraulic systems.

Single-acting telescopic cylinders and double-acting telescopic cylinders are not interchangeable, and their individual operating characteristics can cause malfunction if inappropriately placed. Visit our Guide to Buying Telescopic Cylinders to learn more about your options.

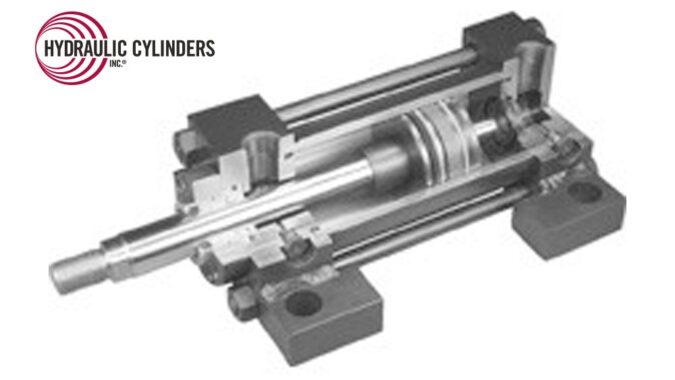

Telescopic Cylinder Stages and Seals

The correct number of stages for your custom telescopic cylinder design will depend on the demands of your planned use. For instance, extended reach can be achieved through adding more stages. However, with each additional stage, the cylinder’s overall load capacity and stability will be slightly lowered. Various design elements can be used to resist deflection caused by the weight and load of the extended telescopic cylinder.

Not sure of your best solution? Contact HCI to discuss your requirements.

Load Capacity

Precision is vital in designing custom telescoping cylinders. The extending telescoping stages must be engineered in relation to the load weight to prevent damage or shutdowns. Bore size, cylinder length, and other factors must be considered to ensure that your cylinder can stand up to the rigors of your job site.

Working Conditions

Working conditions and job site environments significantly impact custom telescopic cylinder design. Temperature, exposure, and other factors dictate the specifications to which the cylinder is built. For example, cylinders operating on offshore oil rigs will have different needs than telescopic cylinders used in construction. Adjusting working cycles, operational capacities, and more will make sure your cylinder performs as expected despite rugged conditions.

HCI Delivers Built-to-Last Custom Telescopic Hydraulic Cylinders

When your application needs a custom telescopic cylinder, don’t settle for “good enough.” Instead, choose Hydraulic Cylinders, Inc. as your full-line supplier. As one of the industry’s most trusted distributors of aftermarket and replacement hydraulic cylinders, HCI works with USA-owned and operated partners to engineer custom telescoping cylinders that meet every specification. Contact us or request a quote to get started.