Repacking Your Hydraulic Cylinder: A Guide

Over time and with extended use, the seals in your hydraulic fluid will naturally wear down and degrade. To keep your systems up and running, you can perform hydraulic cylinder repacking, a process that involves disassembling the cylinder, removing components, and installing new seals. While this may sound daunting, the process is straightforward and takes less time than you may think. In fact, repacking is considered a standard maintenance task and is necessary to keep your cylinder in top shape.

Over time and with extended use, the seals in your hydraulic fluid will naturally wear down and degrade. To keep your systems up and running, you can perform hydraulic cylinder repacking, a process that involves disassembling the cylinder, removing components, and installing new seals. While this may sound daunting, the process is straightforward and takes less time than you may think. In fact, repacking is considered a standard maintenance task and is necessary to keep your cylinder in top shape.

In addition to providing an easy-to-understand 10-step repacking guide, this blog will take you through identifying when to repack your cylinder, how to test your cylinder, and why repacking is necessary. Keep reading to learn more!

How Do You Know if Your Cylinder Needs Repacking?

The number one indicator that your cylinder may need to be repacked is leaking hydraulic fluid. This is often a result of worn, used, or damaged seals. However, there are other indicators. Signs that your cylinder needs repacking can include:

- Hydraulic drift

- Fluid leaks

- Changes in performance

- Difficulty loading or moving components

To determine if your cylinder needs repacking, you can perform tests and observe the results.

Testing a Hydraulic Cylinder

To test your cylinder, you can:

- Fill your cylinder with hydraulic fluid.

- Expel all air with several full strokes.

- Fully pressurize and extend the cylinder and check for leaks.

- Retract the cylinder and inspect for leaks.

- Run an internal bypass test.

If, after testing, you observe any leaks or any of the symptoms listed above, your cylinder may need to be repacked.

Preparing to Repack Hydraulic Cylinders

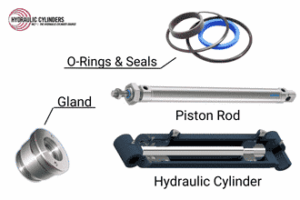

Proper preparation is essential before repacking a hydraulic cylinder. First, be sure you are familiar with navigating your hydraulic cylinder components. Understanding various cylinder parts will expedite repacking and make the overall process easier.

Your workspace should be clean to prevent contamination during disassembly and repacking. To maintain organization, wait to open your hydraulic cylinder repacking kit until you are ready to install the new seals. Before repacking, be sure to gather all the necessary supplies, including:

- A hydraulic cylinder repacking kit compatible with your cylinder model

- Clean replacement hydraulic oil

- A wrench for removing the piston rod

- Several clean, lint-free clothes for cleaning parts and wiping spills

- A large container for catching old hydraulic oil

Safety Tip: If you plan to use equipment for raising and lowering heavy objects or weight-bearing purposes, brace the supported weight with jacks or blocks. This critical step helps prevent accidental injury to yourself and damage to expensive cylinder piston assemblies.

How to Repack a Hydraulic Cylinder in 10 Simple Steps

Use this outline as a guide to repacking a hydraulic cylinder. Use caution and follow each step carefully to ensure a refreshed, leak-free cylinder.

- Release all pressure from the cylinder.

- Loosen and remove the hydraulic lines from the cylinder.

- This allows the last bit of pressure to escape the cylinder.

- Stabilize the cylinder before removing the pin from the rod end.

- Ensure the hydraulic cylinder is supported and won’t drop.

- Remove the gland from the cylinder. This process will vary based on your cylinder manufacturer.

- Some glands are bolted and can be unbolted for removal.

- Other glands require inserting a special tool into small holes to turn the gland where the rod exits the cylinder. The gland may require a slight tap or bump with a hammer to break it loose. Once loose, it should easily unscrew and pull away onto the piston rod.

- Remove the piston rod from the cylinder.

- Prevent the piston rod from contacting other metal objects or falling onto the ground. Otherwise, you risk contaminating the piston rod or damaging its surface. Ensure the fine threads inside the cylinder do not become damaged when removing the rod, as damage to these components may be costly.

- Remove the piston from the rod. This process will vary based on your cylinder manufacturer.

- A threaded rod may have the piston directly attached, or have a nut and bolt holding it in place.

- When the rod is free from the cylinder housing, remove the piston from the rod.

- Tip: Keep all parts in the correct order and take a photo for reference if needed!

- Replace seals and O-rings on the piston and gland.

- Ensure each groove is free of debris before replacing it with the new part.

- Replace these components one at a time to minimize confusion and ensure correct placement. Take care to identify and use the correct seals.

- Note: Uniform installation is key, as some seals are very thin and can be easily damaged with improper installation.

- Reassemble the piston to the rod.

- Always use a thread locking adhesive when replacing the piston rod bolt. Oil and clean all parts well before reassembly.

- Reinsert the gland into the cylinder.

- Never use a thread-locking substance on the gland threads.

- Replace all hydraulic lines and test for leaks around the new seals.

- Test for leaks around the new seals.

Repacking a Hydraulic Cylinder: Why Does it Matter?

Repacking is a necessary part of maintaining your hydraulic cylinder. As seals and internal components wear out over time, there is an increased risk of leaks and reduced performance. By replacing these parts, you can ensure that your cylinder will continue to perform at maximum capacity and without damage. Additionally, repacking is essential to avoid expensive repairs and to prevent costly downtime. With routine maintenance and ongoing inspections, you can save time, money, and your equipment from potential damage.

Hydraulic Cylinders, Inc. is Your #1 Source for Hydraulic Cylinders and Components

For top-quality replacement hydraulic cylinders, component parts, and repacking kits you can count on, we are your best partner. With decades of experience and expertise, we pride ourselves on supplying you with precisely what you need for any hydraulic project or system. Our trained specialists are experts in the field and are prepared to assist you with any questions or needs.

Contact Us

Contact us with any questions or to learn more. Request a quote to begin your hydraulics order today.